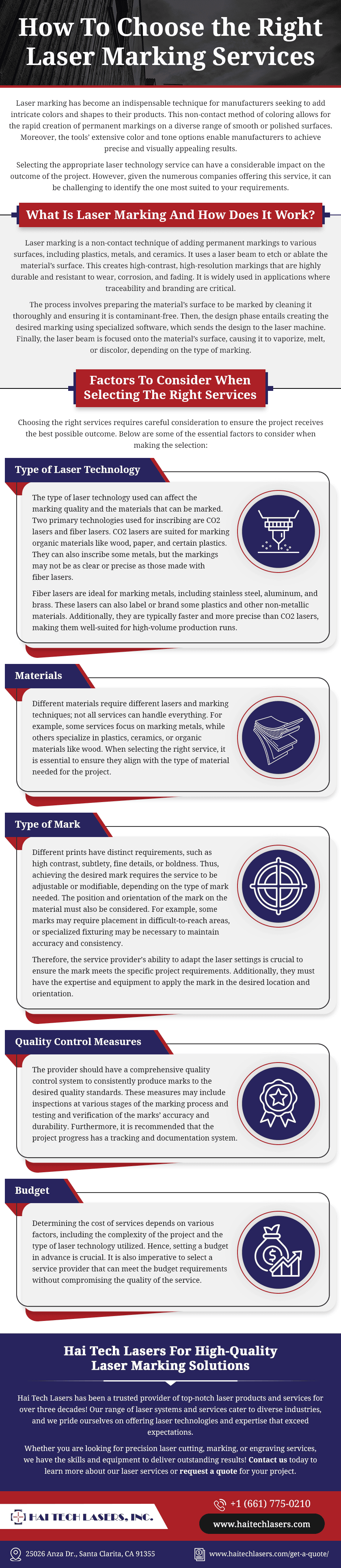

Laser marking has become an indispensable technique for manufacturers seeking to add intricate colors and shapes to their products. This non-contact method of coloring allows for the rapid creation of permanent markings on a diverse range of smooth or polished surfaces. Moreover, the tools’ extensive color and tone options enable manufacturers to achieve precise and visually appealing results.

Selecting the appropriate laser technology service can have a considerable impact on the outcome of the project. However, given the numerous companies offering this service, it can be challenging to identify the one most suited to your requirements. This article will outline the critical aspects to remember when selecting a service to ensure optimal outcomes.

What Is Laser Marking and How Does It Work?

Laser marking is a non-contact technique of adding permanent markings to various surfaces, including plastics, metals, and ceramics. It uses a laser beam to etch or ablate the material’s surface. This creates high-contrast, high-resolution markings that are highly durable and resistant to wear, corrosion, and fading. It is widely used in applications where traceability and branding are critical.

The process involves preparing the material’s surface to be marked by cleaning it thoroughly and ensuring it is contaminant-free. Then, the design phase entails creating the desired marking using specialized software, which sends the design to the laser machine. Finally, the laser beam is focused onto the material’s surface, causing it to vaporize, melt, or discolor, depending on the type of marking.

Factors To Consider When Selecting the Right Services

Choosing the right services requires careful consideration to ensure the project receives the best possible outcome. Below are some of the essential factors to consider when making the selection:

Type of Laser Technology

The type of laser technology used can affect the marking quality and the materials that can be marked. Two primary technologies used for inscribing are CO2 lasers and fiber lasers. CO2 lasers are suited for marking organic materials like wood, paper, and certain plastics. They can also inscribe some metals, but the markings may not be as clear or precise as those made with fiber lasers.

Fiber lasers are ideal for marking metals, including stainless steel, aluminum, and brass. These lasers can also label or brand some plastics and other non-metallic materials. Additionally, they are typically faster and more precise than CO2 lasers, making them well-suited for high-volume production runs.

Materials

Different materials require different lasers and marking techniques; not all services can handle everything. For example, some services focus on marking metals, while others specialize in plastics, ceramics, or organic materials like wood. When selecting the right service, it is essential to ensure they align with the type of material needed for the project.

Type of Mark

Different prints have distinct requirements, such as high contrast, subtlety, fine details, or boldness. Thus, achieving the desired mark requires the service to be adjustable or modifiable, depending on the type of mark needed. The position and orientation of the mark on the material must also be considered. For example, some marks may require placement in difficult-to-reach areas, or specialized fixturing may be necessary to maintain accuracy and consistency.

Therefore, the service provider’s ability to adapt the laser settings is crucial to ensure the mark meets the specific project requirements. Additionally, they must have the expertise and equipment to apply the mark in the desired location and orientation.

Quality Control Measures

The provider should have a comprehensive quality control system to consistently produce marks to the desired quality standards. These measures may include inspections at various stages of the marking process and testing and verification of the marks’ accuracy and durability. Furthermore, it is recommended that the project progress has a tracking and documentation system.

Budget

Determining the cost of services depends on various factors, including the complexity of the project and the type of laser technology utilized. Hence, setting a budget in advance is crucial. It is also imperative to select a service provider that can meet the budget requirements without compromising the quality of the service.

Hai Tech Lasers for High-Quality Laser Marking Solutions

Hai Tech Lasers has been a trusted provider of top-notch laser products and services for over three decades! Our range of laser systems and services cater to diverse industries, and we pride ourselves on offering laser technologies and expertise that exceed expectations.

Whether you are looking for precision laser cutting, marking, or engraving services, we have the skills and equipment to deliver outstanding results! Contact us today to learn more about our laser services or request a quote for your project.